CRITICAL OPERATIONAL SUCCESS

For proven solutions to complex pressure control issues, Cudd delivers critical well intervention services in a range of applications for even the most demanding environments. Our well control specialists offers quick, safe, reliable solutions in a variety of applications to serve your immediate operational needs.

Onshore/Offshore Hot Tap Services

For onshore and offshore hot tapping capabilities on time and within budget, Cudd offers decades of

experience and access to resources for an unparalleled execution.

When conventional pressure relief fails, we can perform a hot tap procedure by drilling a hole in a pipe or

tube to gain access to a wellbore if wellhead valves become inoperable.

We are the pioneers of subsea hot tap and valve drilling operations, developing a first-of-its-kind subsea well intervention unit designed to reduce costs and minimize the environmental impact.

Our remote-operated tool is rated to work at pressures up to 1,000 psi.

Ultra-Compact Hot Tap Engineered for Rapid Deployment

The only hot tap on the market rated API 6A 3G eases logistics concerns by offering a smaller footprint, yet still delivers the same high-quality performance our customers have come to expect from Cudd. Because of its compact size, the unit can be flown at a moment’s notice on a private aircraft and transported in the bed of a pickup truck to arrive on location for operation when you need it. View video to learn more about this efficient, sleek execution.

Click here for a PDF

| Standard Hot Tap Capabilities |

|---|

| Drill thru coiled tubing, production tubing, drill pipe, drill collars, caning, bull plugs, blanking flanges, pipelines |

| Leak proof entry for pipeline access |

| Designed for onshore and offshore operations |

| 10,000 psi working pressure, including H2S environments |

| Bit sizes range from ½’’ to 1 ¼’’ |

| Saddle size range from 1 ½’’ to 36’’ |

| Can be operated manually or pneumatically |

| Unit is small and compact and weighs approximately 200lb |

| Complete pressure balanced system to allow for long stroke capabilities |

| Ultra-Compact Hot Tap Capabilities |

|---|

| Pressure-balanced design for safe, easy operation |

| Built for pressures up to 10,000 psi |

| Designed for H2S environments |

| Engineered with an 18-in. stroke length |

| Fast, nearly effortless deployment |

| Ideal for tight spaces |

| Environmental friendly hydraulic working fluid |

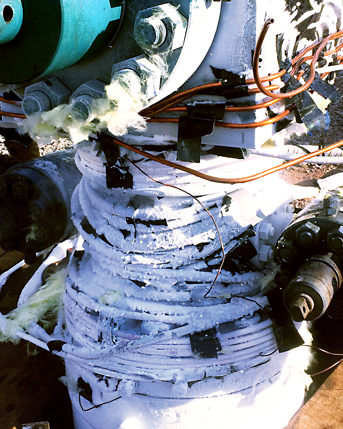

Freeze Applications

For more than 20 years, our cryogenic and dry ice freeze operations have provided access to critical

equipment, onshore and offshore, so that crews can perform maintenance or repairs while the wellbore remains

pressurized. Over the years, we have perfected the technique to increase the power of the temporary ice

plug, creating a highly functional field tool so that your team keeps cool under pressure.

Staging our unique approach to freeze operations allows for the removal and replacement of faulty equipment

with the peace of mind that the plug will hold for the length of time required to properly perform repairs

on BOPS, valves, production trees, and other non-cylindrical items.

We also perform cryogenic freeze operations on tubulars of all sizes, successfully plugging through multiple

casing and cement layers for a faster freeze that holds longer.

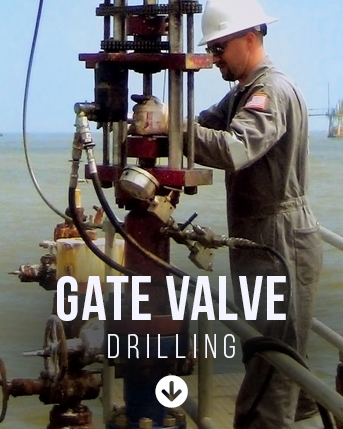

Gate Valve Drilling

Have a pressure control situation that requires a different point of entry? Gate valve drilling offers an

effective approach by drilling out an inoperable gate or plug while it’s in the closed position. This is

performed while maintaining pressure downstream of the gate or valve.

Doing this allows for accurate monitoring of the pressure, a controlled release of the pressure, or provides

the opportunity to pump in fluids to freeze or kill the well. We have the capabilities to drill a gate or

TIW valve to its full inner diameter.

For longer reach operations, our pressure-compensated gate valve units can access drilling points several

feet away from the unit. Available units deliver up to 15,000-psi pressure ratings in H2S

service.

| Capabilities |

|---|

| Gate valves, ball valves, TIW valves, casing hangers, plug valves, obstructions in the wellhead |

| Engineered mills custom built to mill every valve type and material efficiently |

| 15,000 psi working pressure, including H2S environments |

| Designed for onshore and offshore operations |

| Mill sizes range from 1’’ to 11’’ |

| Full hydraulic units |

| Compact and weighs approximately 750 lbs |

| Pressure balanced system allowing for long stroke capabilities up to 30 ft |